Capabilities

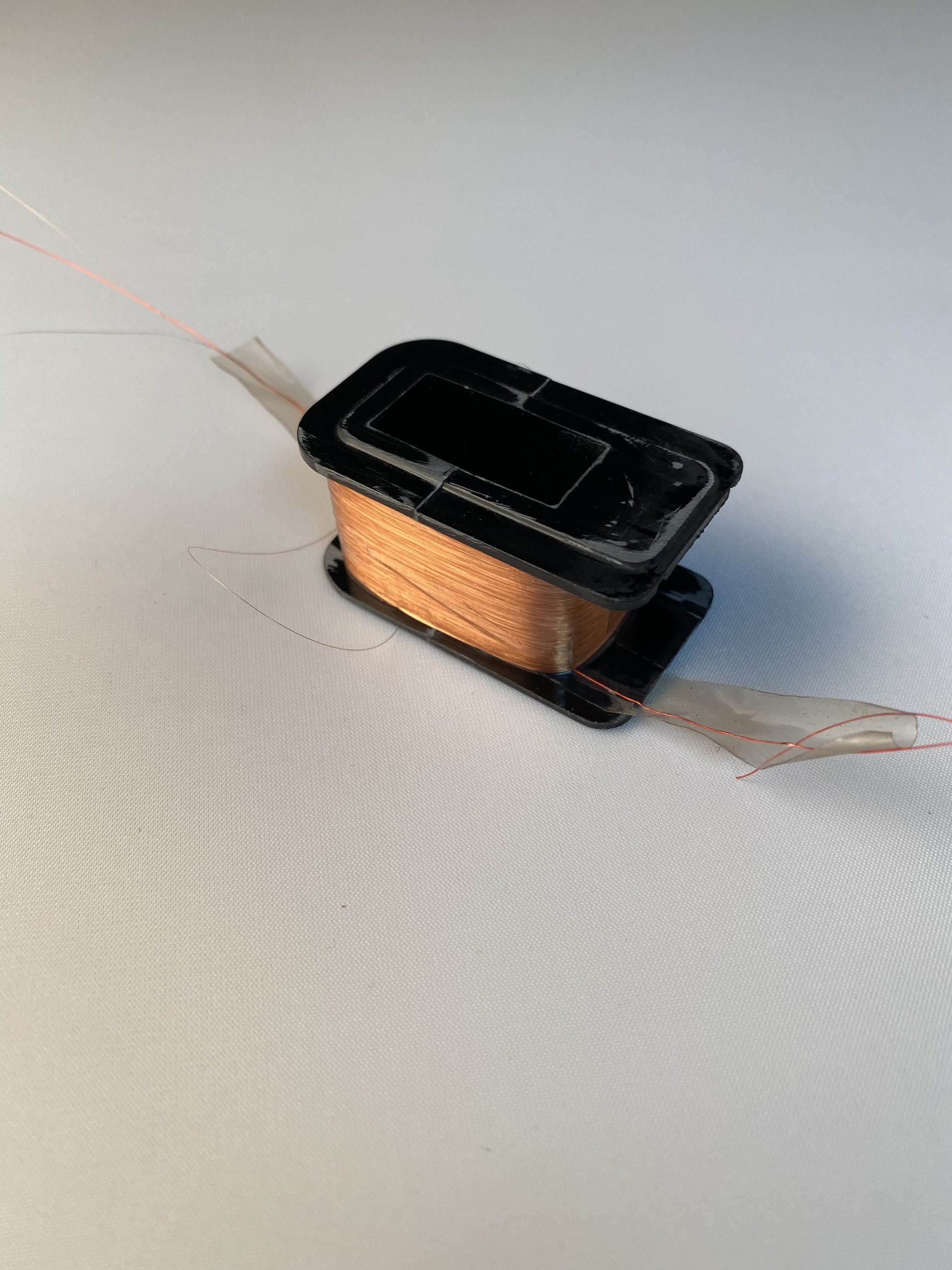

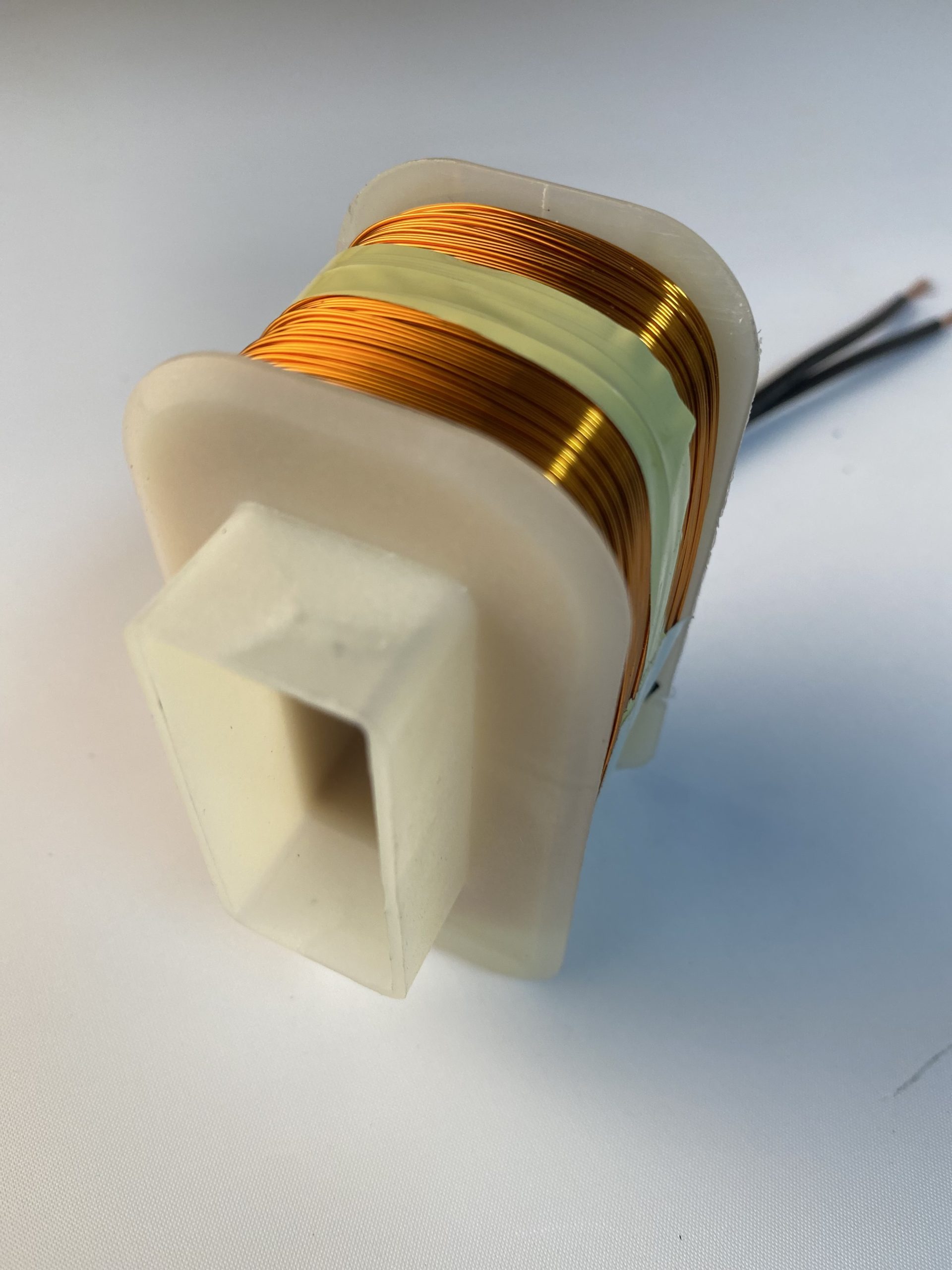

Custom Transformers, Precision Custom Coils, Custom Coil Winding and more…

At Dufrane, our specialty as a Precision Coil Manufacturer is the ability to meet the requirements of your custom transformer and electromagnetic coils needs using a solution-based approach. Whether it’s Custom Electric coils and Custom Wound Coils, Step Down Transformers, Single Phase Transformers, Toroid Transformers (Toroids), Toroid Coils, Chokes, Reactors and Inductors, etc. – our engineers and facilities allow us to produce state-of-the-art Coil Winding solutions to meet your needs. This includes Custom transformers of all types.

Versatile Coil Winding expertise and Custom Coil Manufacturer

Our versatility in coil winding includes small, printed circuit board coil winding custom transformers, single-phase transformers, step-up transformers, step-down transformers, and toroid transformers as well as other challenging wound coil solutions from 10mW to 25KVA as well as 3-phase transformers from 7VA to 75KVA. Your “Special Application” can be designed with any style of custom termination required. That’s our specialty.

Custom Coils, Coil Winding – Build to Print and Reverse Engineering

Our capabilities include the following areas of expertise in the area of industrial power solutions including custom small transformers, industrial transformers, toroid coils, custom windings, custom coils and other wound coils to serve you:

- Build to Print and Contract Manufacturing

- Reverse Engineering (including obsolete transformers)

- Design and Build

- Machining

- Custom Electric Coils and Copper Wire Coil Solutions

- Special Materials and Processes

a broad range of state-of-the-art computerized winding equipment to precisely wind a variety of materials up to 24″ in diameter. Our 100,000 square foot facility enables us to produce large volume electromagnetic coils, custom transformers, and electric coils orders on a regular contract manufacturing basis.

Our advanced testing equipment and quality team test and certify 100% of all completed devices before they ship.

Special Materials and Processes when Coil Winding (Winding Coils)

We typically use special materials and processes to ensure the environmental integrity of each transformer, coil winding, wound coil, inductor, reactor, choke, Industrial transformer, etc. will meet the environmental requirements of your special project, including VPI, Epoxy encapsulation and molding, Plastisol, and many other materials as needed.

In addition, we can provide design services leveraging our talented engineering team for a complete turnkey custom transformer design – and manufacture those very designs.

We also specialize in build-to-print/contract fabrication of your own designs, with value-added engineering to effect potential cost savings and product improvement.

Are Obsolete components a problem for you? Don’t worry, it’s a problem for many – Dufrane has the ability to reverse engineer Custom Coils, Custom Coil Windings, Custom Transformers to solve those problems and keep your production line going.

“Turnkey” Rapid Prototyping of Custom Coils and Custom Transformers

Dufrane’s team can rapid prototype custom transformers (no minimums) so you can check the product before a production run.

With our in-house machining capability, we can supply limitless choices for mounting, cabling and termination on all Dufrane custom electromagnetics coils and custom transformers.

Quality Custom Windings

Our Quality is legendary; we are typically running between 98-99% quality rating on returns which includes small high volume runs.