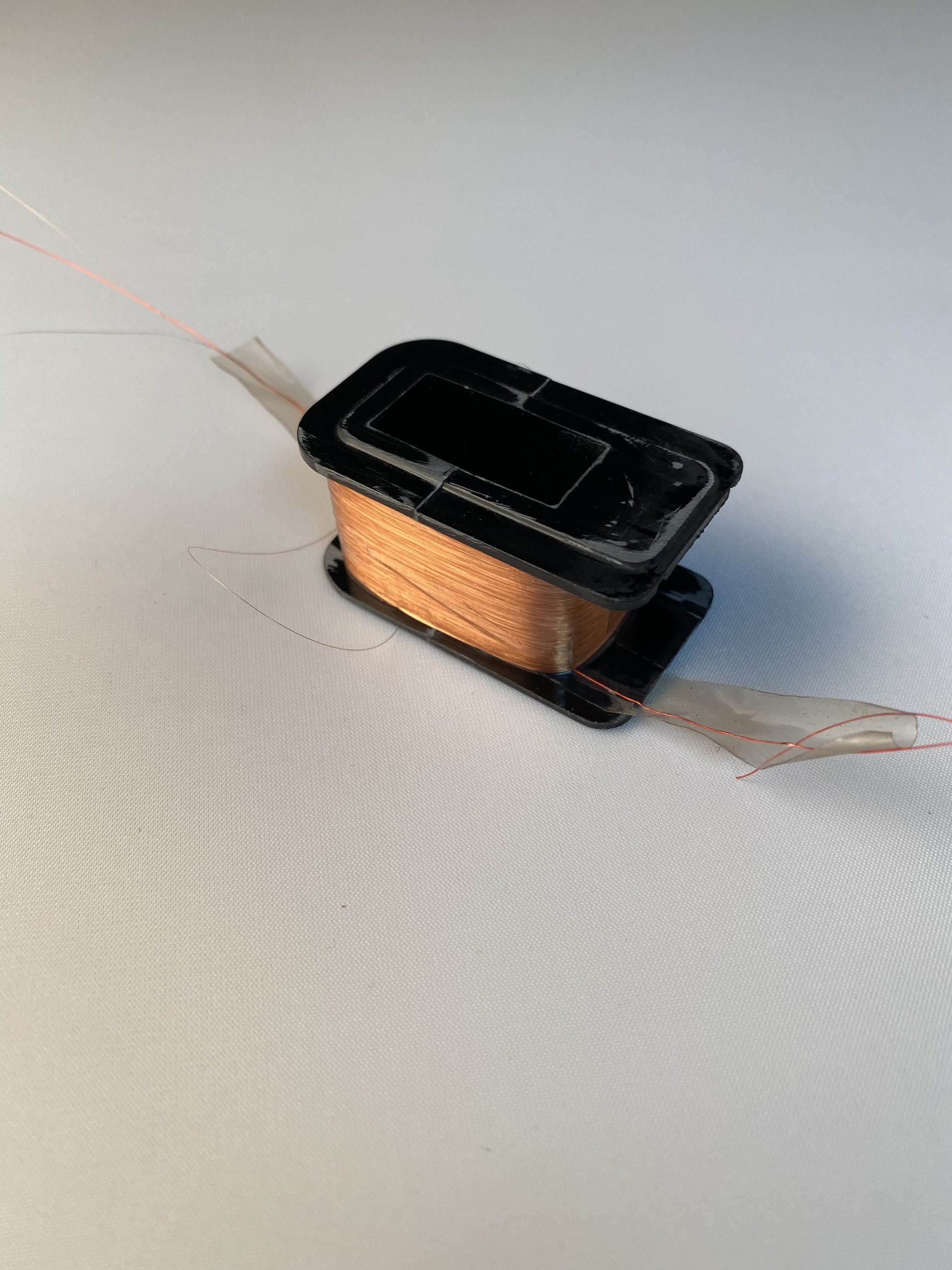

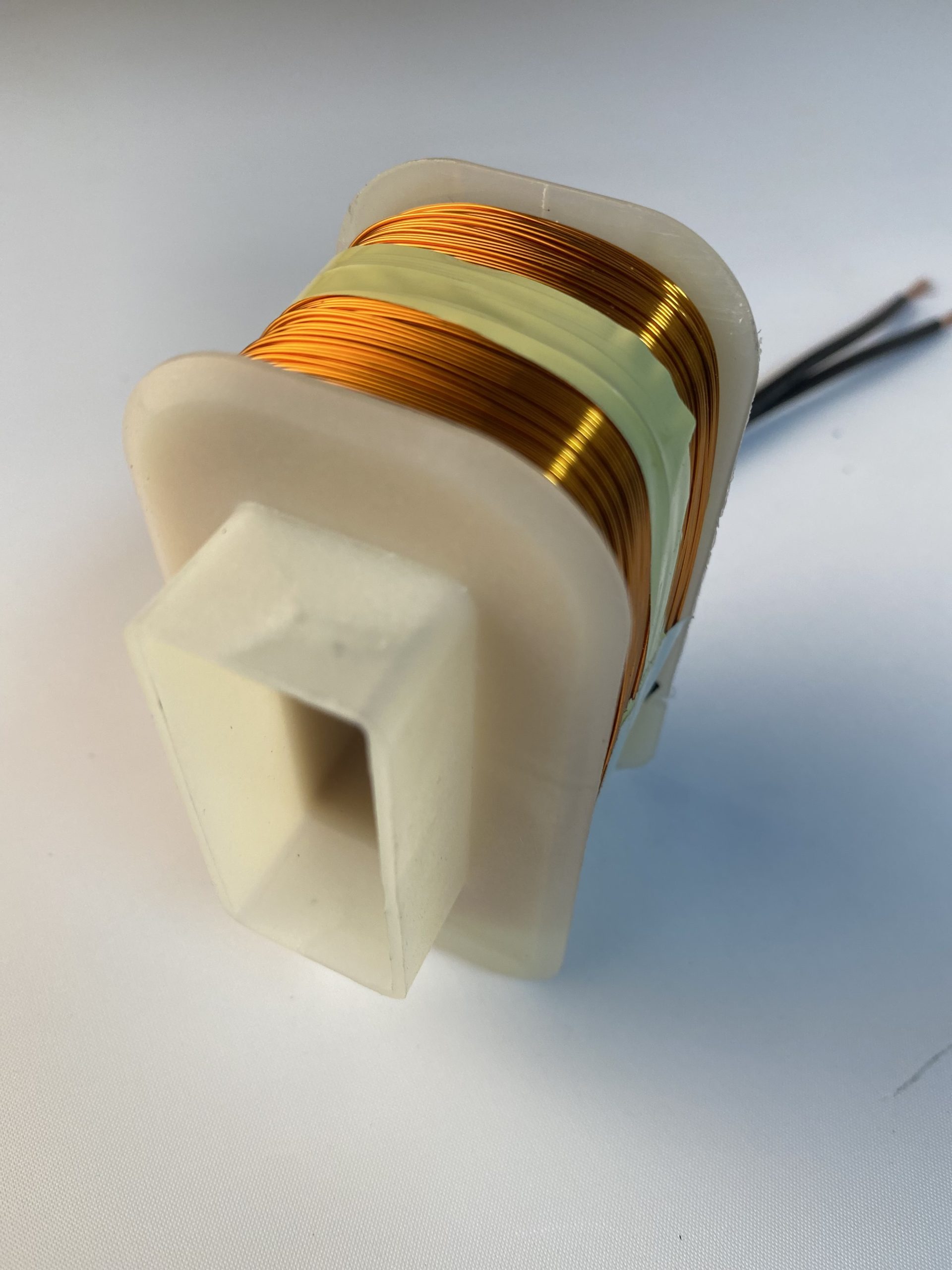

Precision Machining

Dufrane now has full in-house machining capabilities which enables us to add value to our custom electromagnetic solutions – not only providing you with the highest quality windings and custom transformers to solve your power system challenges, but also providing you with a more complete product. Our machining capabilities have expanded, and we now offer the ability to be a stand-alone resource for precision machined parts.

Machining Center

Dufrane Technologies Machining Division is capable of machining a wide array of parts not just for our Electromagnetics customers, Dufrane Nuclear Shielding Customers, etc. – but also for other manufacturers who need affordable precision parts.

From custom low volume jobs – such as fixtures, prototypes and “one-off” development projects – up to high production jobs and custom lot sizes in between.

We have the ability to work with many different materials – including but not limited to plastics, aluminum, copper, brass and an assortment of different grades of steel.

Dufrane has a “project management” mentality, and we prefer to keep an open line of communication and transparency with our customers in order deliver a finished product that is precise, accurate and on time.

Machinery

The machinery we have includes:

HAAS TM-1

A tool room 3 axis CNC mill that has a max bed travel capacity of 30”x12” and can drill, tap, ream, mill, slot, engrave text and a series of other applications on both simple and complex parts. This mill is capable of producing in all quantities to strict tolerances.

HAAS TL-2

A CNC lathe with an 8” chuck and a max bed capacity of 48”. This lathe is capable of turning, boring, drilling, tapping, grooving and threading on simple and complex parts as well. It can hold and repeat to very strict tolerances to within a few tenths in all quantities.

BRIDGEPORT WITH TRAK CNC PENDANT

A 2 axis CNC mill with a hand operated z axis. This mill can be programmed for milling, drilling, tapping, reaming, slotting, as well as various other applications. Great for making fixtures and small lots of parts. Holds tight tolerances and holds repeatability.

TRAK QUICK CELL QCM-1

A 3 axis CNC mill with a max bed travel of 12”x10” which can be programmed for milling, drilling, tapping, slotting, reaming and various other applications. Can hold and repeat tight tolerances. Good for running small job lots, 1-piece orders and production lots.

HAAS ST-20Y

A CNC lathe with live tooling and a 6” chuck with a max z axis travel of 16 inches. Can turn, groove, slot, drill, bore, tap, thread and a variety of other applications. Great for jobs of all quantities. Can hold tolerances to within a few tenths and has excellent repeatability.

BROTHER SPEEDIO R450 X2

17″ X 12″ WORK ENVELOPE WITH HIGH SPEED AUTOMATIC PALLET CHANGER FOR CONTINOUS MACHINING

AMERA SEIKI MC 2660

60″ X 20″ WORK ENVELOPE HEAVY DUTY 50 TAPER MACHINING CENTER

MAZAK NEXUS 510C

40″ X 20″ WORK ENVELOPE WITH AUTOMATIC PALLET CHANGER FOR CONTINOUS MACHINING

MAZAK NEXUS 5X

11.8″ X 11.8″ WORK ENVELOPE 5 AXIS MACHINING CENTER

DOOSAN 670L

26″ X 70″ SLANT BED HEAVY DUTY LATHE

OKUMA LH55-N

22″ X 119″ BIG BORE LATHE

OMNITURN GT 75

SMALL GANG TOOL LATHE WITH AUTOMATION OPTIONS FROM BOWL AND TRACK FED PARTS FOR CONTINOUS MACHINING

We also utilize hand operated Bridgeport Mills, bandsaws and parts tumblers for cleaning and deburred parts. Also skilled in hand deburring parts, ensuring that we deliver a beautiful and accurate machined product every time.

Competitive Rates and Lead Time

Dufrane will offer customers highly competitive pricing for the area, and the ability to provide you with turnkey quotations or work with you in partnership to provide quotations based on customer supplied materials. We also pride ourselves with a very high on-time delivery rate and competitive lead times to insure your own production schedule is not driven by machined parts.