Reverse Engineering

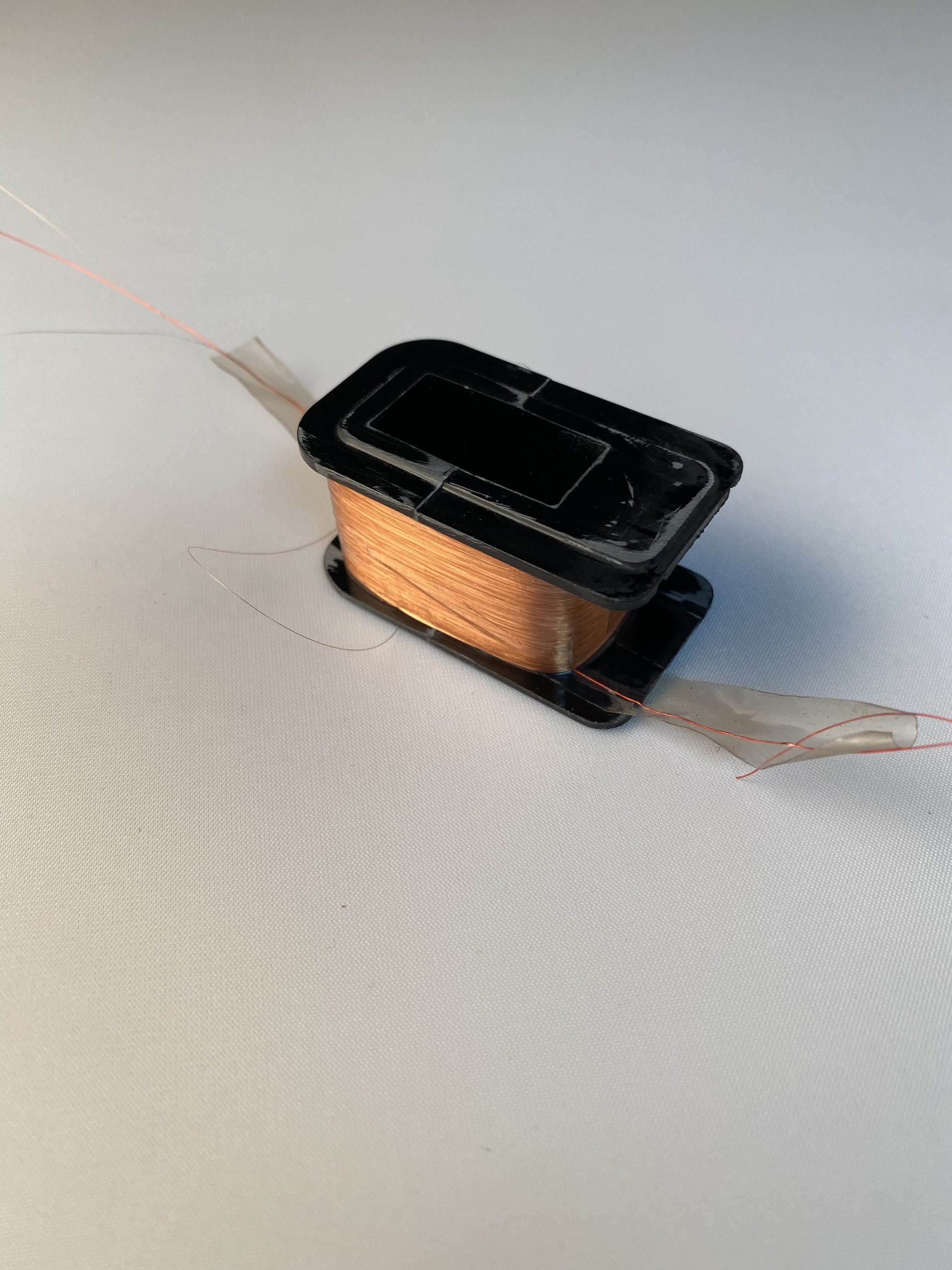

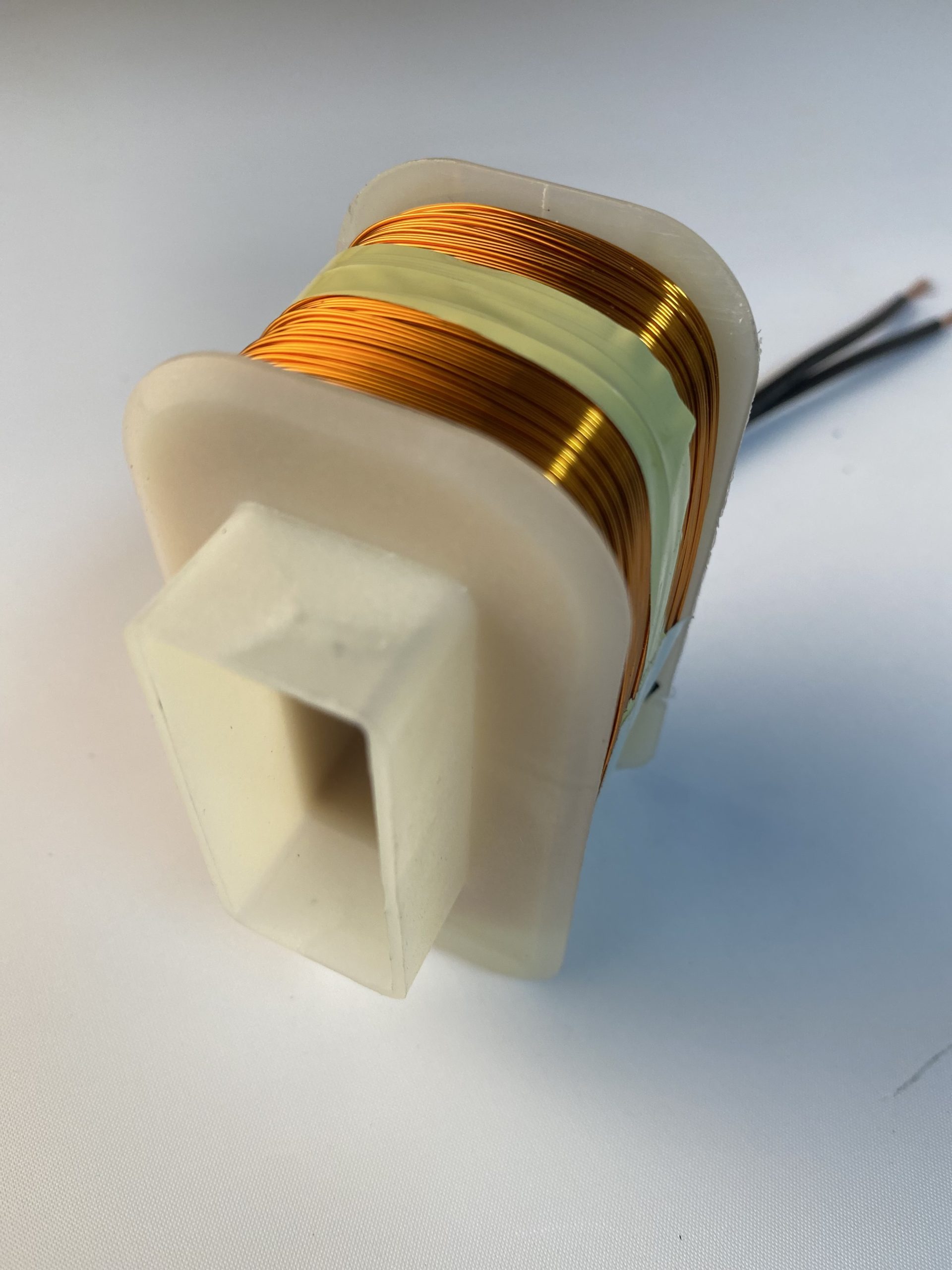

Reverse engineering of custom transformers (small power transformers, toroidal transformers, current transformers, pulse transformers, custom electromagnetic windings and coils) starts with your need. Usually, the need stems from extinct suppliers, obsolete parts, long lead times, quality problems, etc. Normally this involves a sample to analyze – and an understanding of the circuit of which the transformer is a component of.

Dufrane has extensive experience reverse-engineering many different products and has a solid reputation in producing a replacement OEM part at low cost, and with value added engineering as well.

Exhaustive analysis is performed and testing is performed to gain a knowledge of the full mechanical and electrical properties of the part to be reverse engineered (typically and old, obsolete transformer). Care is taken to insure that materials that are equal to (or exceed) OEM specifications are used. Finally, a thorough understanding of the application and how the transformer is used in the application is reviewed with the customer so that we have a thorough understanding of how the electromagnetic component is used prior to the output of drawings to be used in manufacturing the part.